Learned a lot lending an editorial hand here:

MIT Sloan Management Review, May 27, 2021

by ManMohan S. Sodhi and Christopher S. Tang

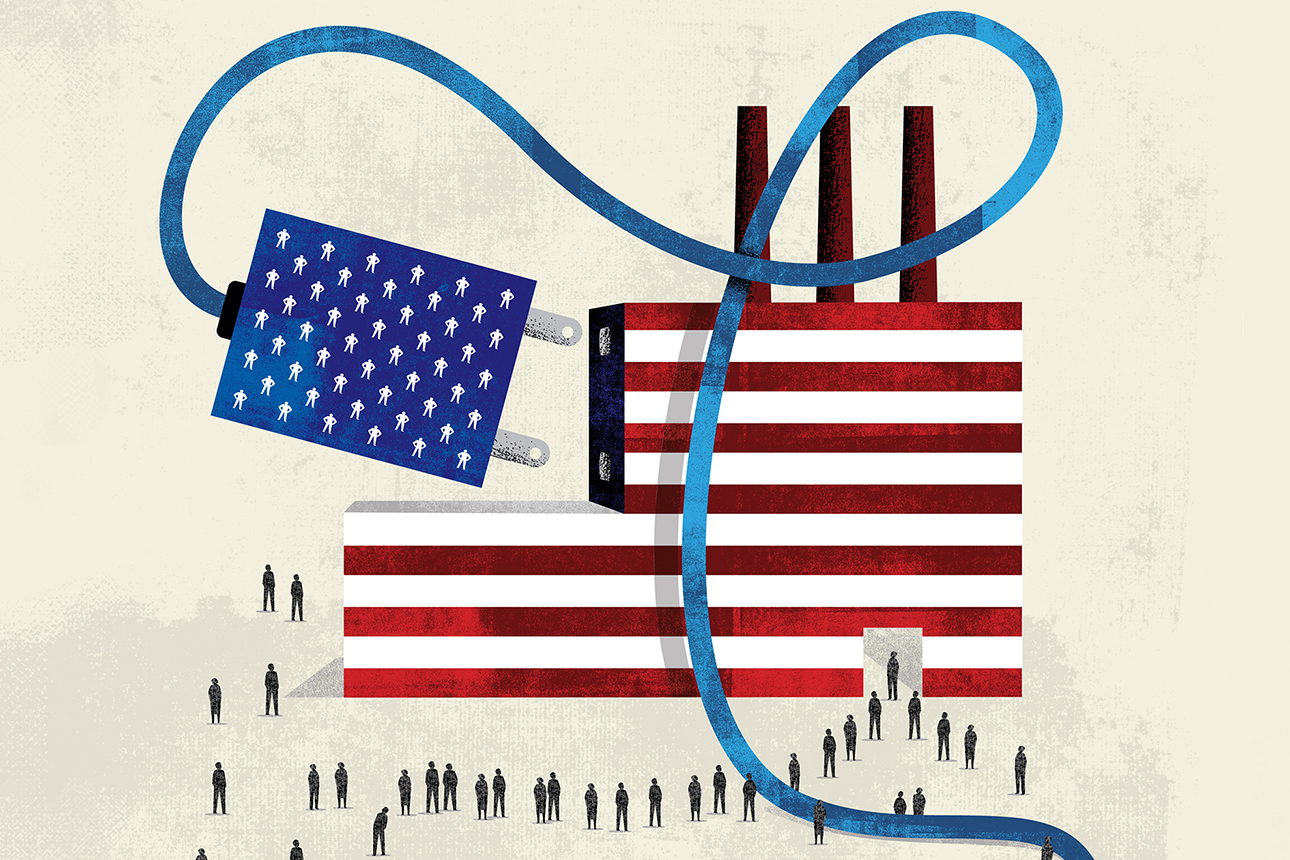

Image courtesy of Michael Austin/theispot.com

Photographs of doctors and nurses wearing garbage bags to protect themselves from infection are among the most indelible images of the COVID-19 pandemic. They also testify to the limitations of the U.S. Strategic National Stockpile (SNS). By the end of March 2020, as the first surge of COVID-19 exceeded 20,000 new cases detected per day, it was woefully clear that the United States’ emergency stockpile of essential medical supplies could not meet the demand for personal protective equipment (PPE), ventilators, and other materials urgently needed to battle the pandemic and save lives.

Since then, there has been plenty of finger-pointing regarding the inability of the SNS to live up to its mandate. But none of that acknowledges the reality that, because of the scale and rarity of pandemic-level public health crises, no national reserve can reliably provide the materials needed from inventory alone.

In the decade before COVID-19, flu-related hospitalizations in the U.S. averaged 440,000 annually, but in 2020 alone, COVID-19-associated hospitalizations reached 4.1 million. This is a huge spike in need that is nearly 10 times the flu hospitalization annual mean. Moreover, public health emergencies of COVID-19’s magnitude are highly unusual in the U.S. or anywhere else, normally occurring decades apart, which makes the demand spike massive but rare.

After all, the demand challenge for the SNS is to be able to handle the following:

- More severe flus occurring every two to three years, with demand for medical products and equipment being, say, twice the average annual flu hospitalization mean.

- Epidemics and minor pandemics that may occur, say, once every five to 10 years, with demand being as much as three to four times the mean, although the spike may be regional rather than nationwide.

- Severe pandemics occurring once every 20 to 40 years, with demand as high as 10 times the annual mean occurring nationwide.